IBA Timber Prototype House

⸺ Digital by nature

Digitalization is considered to be a promise for the future and a major field for innovation, including for the construction industry. The key areas are referred to as Building Information Modeling (BIM) and ›printing houses‹: comprehensive digital planning and digital manufacturing. While logical and understandable in theory, practical implementation is still in the experimental stage. The associated fundamental planning and cultural change in construction is only slowly becoming apparent.

A research team led by Prof. Achim Menges from the Institute for Computer-Based Design and Production at the University of Stuttgart and architect Dr. Hans Drexler from DGJ Architecture, formerly Jade University of Applied Sciences Oldenburg, have been interested in these questions for many years and combine their research interests with practical implementation in prototypical buildings. In 2015, this led to a cooperation with IBA Thuringia for a research project funded by the Federal Ministry of the Interior's Future Building program, aimed at developing a highly-insulating solid wood construction method based on a prototype building, incorporating the potential of digital planning and production.

The innovative potential of the project and the consideration of one of Thuringia's central, sustainable resources – wood – convinced the IBA advisory board.

The development of the IBA Timber Prototype House began. The starting material, wood from regional production, was made available through early cooperation with Thuringia Forest and industrial partner Rettenmeier Holz, as well as the environmental label ›Holz von Hier‹. A standard spruce wood beam measuring 10 by 20 centimeters formed the basic building block for the further development process.

The development of the IBA Timber Prototype House began. The starting material, wood from regional production, was made available through early cooperation with Thuringia Forest and industrial partner Rettenmeier Holz, as well as the environmental label ›Holz von Hier‹. A standard spruce wood beam measuring 10 by 20 centimeters formed the basic building block for the further development process.

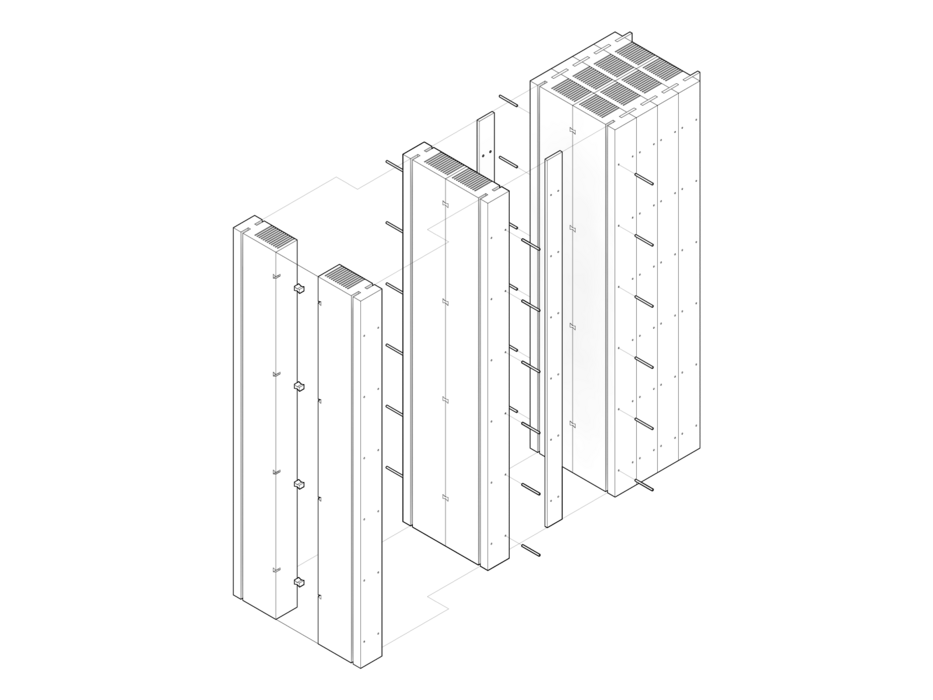

In preliminary studies, a simple basic principle for a component was developed that is suitable for walls, floors, and ceilings at the same time. Based on this, a fully digital, parametric model was created that made all constructive limits and possibilities simulating. The actual design process was not conventionally drawn but controlled via digital parameters. In the result, a multitude of digital models were created in a short time, from which the project team made a selection.

At the same time, a complete data set was available for the actual fabrication of the elements. Initially, with a 7-axis industrial robot, later on a 5-axis CNC milling machine, the over 400 detail-different components were precisely prefabricated and then assembled by a parts were fabricated and afterwards put together like LEGO bricks by the student team. The room modules were transported to the Eiermannbau building in Apolda in five tube-like parts and assembled on-site.

The building was officially opened in May 2019, just in time for the IBA interim presentation ›StadtLand‹ .

The building was officially opened in May 2019, just in time for the IBA interim presentation ›StadtLand‹ .

Ort

IBA Timber Prototype House

Auenstraße 11

99510 Apolda

Contact

- Tobias Haag, Former IBA project leader

Projekt sponsor

- University of Stuttgart - Institute for Computer-Based Design and Manufacturing: Prof. AA Dipl. (Hons) Achim Menges, Oliver Bucklin, Oliver Krieg, Víctor Rodríguez

- Jade University of Applied Sciences in Oldenburg: Hans Drexler, Maria Deilmann, Geronimo Bujny, Anna Bulavintseva

- International Building Exhibition Thüringen

Cooperation partner

Financial support

- Federal Ministry of the Interior, Building and Community

- IBA Thüringen

- ThüringenForst (Sponsors)

- Rettenmeier Holding AG (Sponsors)

- Green Concept Award 2020

- Shortlisted for the Thuringian State Prize for Architectural Culture 2021